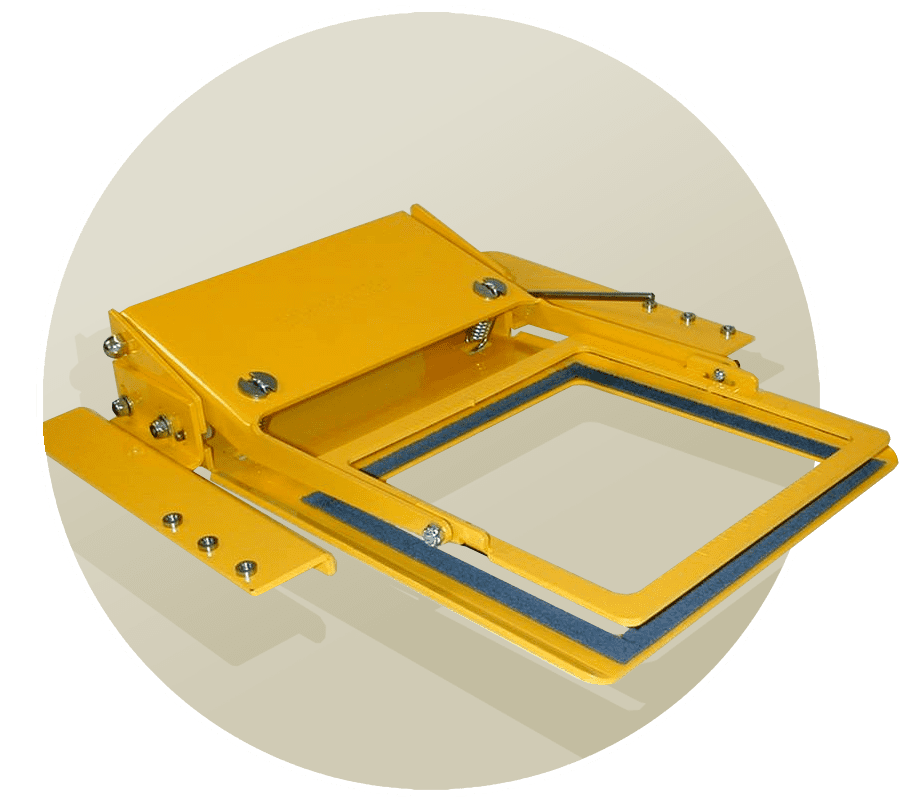

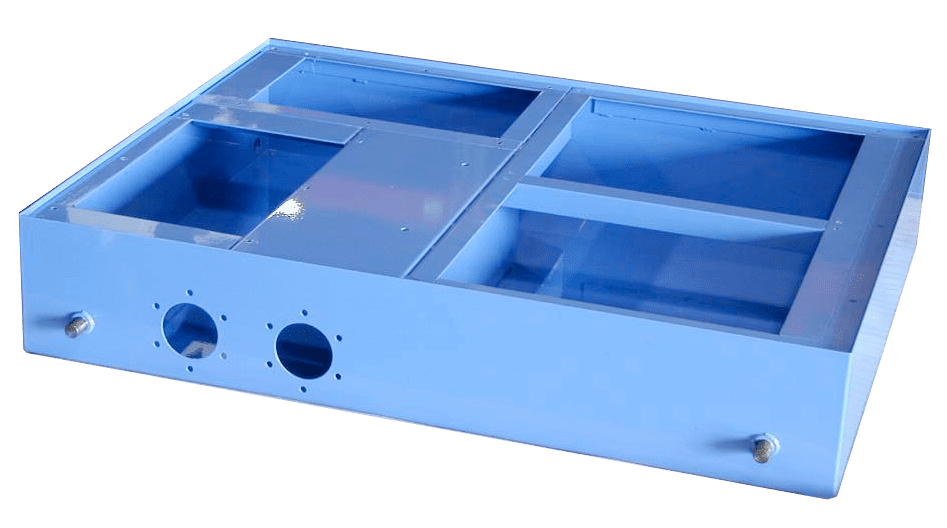

Powder Coating

Powder Coated Weldments and Fabrications

We offer a full-service powder coating shop that can apply powder coat to large and small parts. The powder coating process is designed to produce the highest quality finish to the greatest variety of part sizes and shapes. Powder coating produces a high specification coating, which is very durable and abrasion resistant.

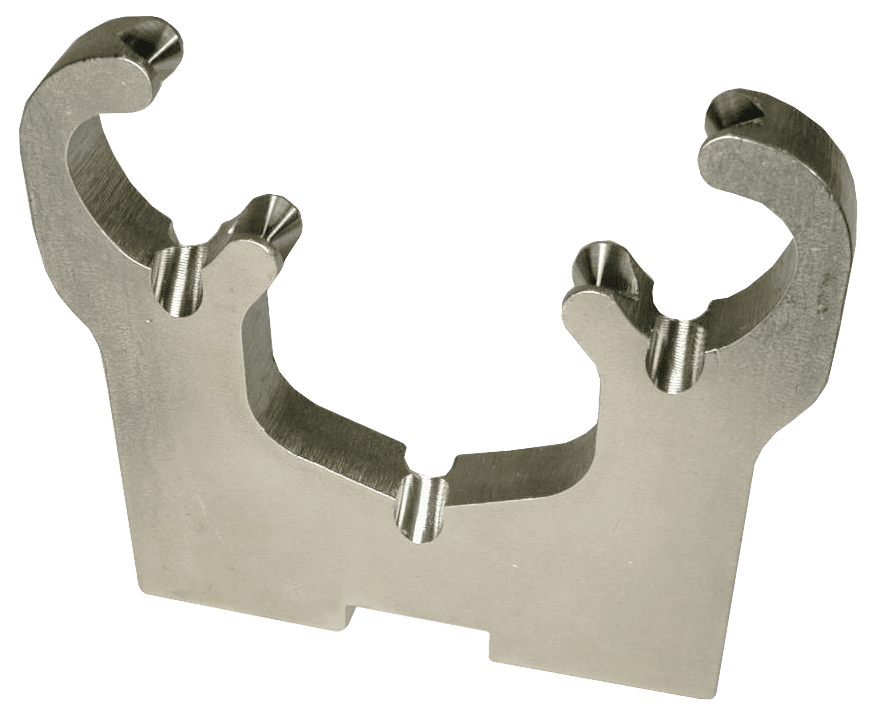

Stainless specialists

Specialists in punching and stamping stainless steel and mild steel parts manufacturing.

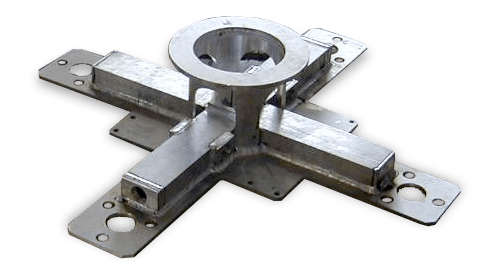

One-stop machine shop

Single, reliable source for high-quality parts. Comprehensive in-house capabilities.

Precision parts fabrication

Experienced craftsmanship using advanced technologies.

Fast Lead Times

Quick, accurate parts turn-around through flexible scheduling

Engineering solutions

Partnering to provide the best solution for your part design.

A powder coated metal fabrication part looks like it was dipped in high gloss paint. A powder coat finish makes a part last, never rust, and never needing waxing. It's a durable industrial powder coating finish for your fabricated part or weldment.

Quality powder coating can have the same hardness of chrome but can take a hit without chipping. Pretreatment is accomplished by abrasive blasting, phosphate spray and masking areas not to be coated.

Thorough Process and Procedure Documentation

We want to be your manufacturing partner rather than just a parts supplier. To remain competitive in a global market, our customers are looking for partners that offer services above and beyond. All processes and procedures are documented.

0+

Years in business

0+

Current Customers

0+

Active Part Numbers

Greater Cincinnati location

4230 Grissom Drive

Batavia, OH 45103

U.S.A.

Batavia, OH 45103

U.S.A.

Give us a call

(513) 732-0800

Contact us by email

Your form submission will be read immediately by Deltec Manufacturing Engineers.